——Nov 15, 2019Shiny Silver Zipper Plating

Shiny Silver Zipper Plating using Dipping Method

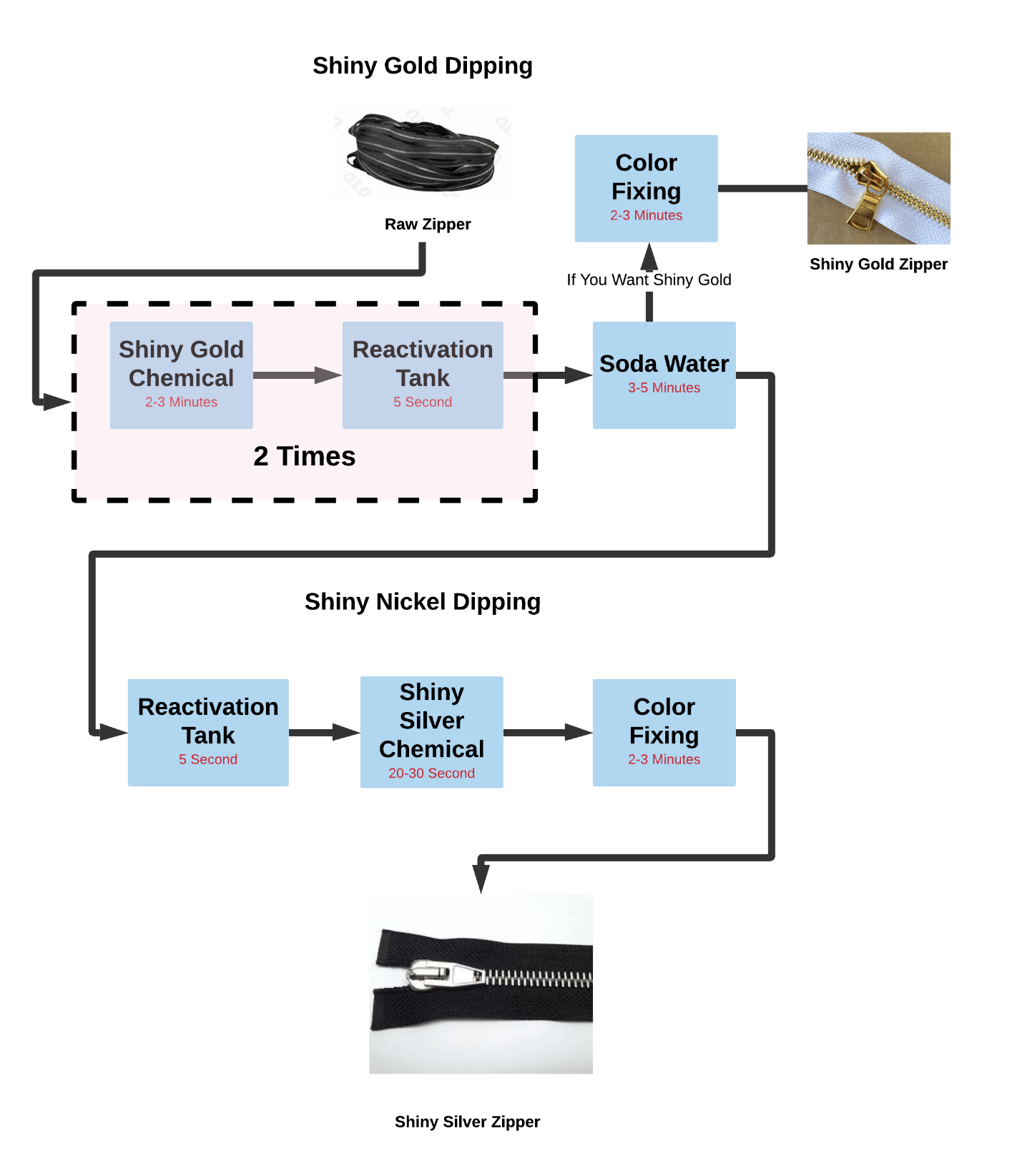

Zipper plating is widely used at metal zippers to increase attractiveness and make the color linger. It allows us to add a variety of colors into metal zippers. Some of the most used zipper plating colors are shiny gold, silver or nickel, rose gold, gun color etc. There are different ways for zipper plating. One of the most used ways are Dipping. It is a manual way of making zipper plating. There is also an automated way which is called Electroplating. It requires different machines to do the plating process. We have already discussed about this in our previous articles. This article is about making Shiny Silver color using Dipping or Manual process.

Figure 1: Shiny Silver Zipper

The process:

The main process is divided into some sub processes. The major parts are 1. Making Shiny Gold Color. 2. Making Shiny Silver Color.

Whenever we will try to make the shiny silver zipper we will have to make it shiny gold first. We have our own chemicals to make both of the colors.

1. Making Shiny Gold Color via Dipping:

First of all, we will take the raw zipper into Shiny Gold Chemical. Here it will stay for 2-3 minutes. We will take the zipper out once the color changes to red color.

We make shiny gold chemical using the following chemicals:

After taking the zippers out from the shiny gold chemical, we need to wash it 3 times. So that we can take all the Shiny Gold Chemicals out from the zipper and Reactivate it for next steps.

The next step is Reactivation

Reactivation tank

After reactivation the zippers turns into golden color

To make the Shiny gold color better we will have to make the Shiny Gold Chemical Dipping and Reactivation again. Then If the requirement is only Shiny gold, we will have to Keep the chemicals to Neutralization Tank and Color Fixing Tank only then the zipper will have shiny gold color for a long time.

But, as we know here, we are making shiny silver color, So, we have to take the Shiny Gold Zippers to Neutralization Tank. This tank makes the color longer lasting. This tank is also called Soda Water. We will have to put the zippers here for 3-5 minutes.

Chemicals used in Neutralization Tank per 3 liters,

For Shiny Nickel/Silver,

We will have to put the zipper again into Reactivation tank for 5 seconds after Neutralization. It will help us to make the zipper prepared for the Shiny Silver Dipping. Then the zipper will go to Shiny Silver Tank.

Shiny Silver Tank is made with the following chemicals

After this process the zipper will be converted into Shiny Silver color. Then the last step is the Color Fixing.

Things to consider:

1. Make sure the Nitric acid is mixed at the Shiny Gold Chemical. Otherwise the shiny gold color will not be good.

2. If the required color appears, we will have to stop the dipping. Otherwise the zipper will be hard and can’t be used easily.

3. Put the chemicals according to the recipe. Otherwise the effectiveness and shiny color will not come.

Related Posts

-

Blog & NewsQLQ Wish All Mothers A Happy Ho

…

Mar 08, 2024

-

Blog & NewsNurse's Day

Whispering is your character, white clothes and white skirts are your characteristics, rescuing the dead and healing the wounded is your bounden duty, nursing patients is your sacred duty, you give patients selfless love, and you turn your…

May 12, 2022

-

Blog & NewsEid Mubarak

Although now we are going through a hard time because of covid -19, but we all believe everything will goes well soon. QLQ family wish you and your family all the best!…

May 05, 2022

-

Blog & NewsHow To Produce Invisible Closed

Our invisible zipper advantages: 1) The standard reciprocating fatigue of invisible zipper is ≥600 times, but our invisible zipper can reach ≥900-1200 times. 2) The standard tension of invisible zipper is ≥480N, but our …

Apr 22, 2022