——Nov 09, 2019Shiny Silver SliderPlating

Electroplating is a universal process of slider plating. Slider plating can only be done at metal sliders. For other types of sliders, we use POM color mixing or painting. Slider plating can be done in both Hanging Plating and Barrel Plating way. Hanging Plating is more advanced and complex way, which gives us outstanding shiny color over the slider. The Barrel Plating is the most used slider plating process, which gives very attractive and long-lasting color over the slider. The plating machines for zipper chain plating and slider plating are construction ally different. There are some extra roller tanks at slider plating machines. Where we put the sliders and start plating. In this article we will discuss about metal slider plating process for Shiny Silver.

Things to Consider Before Shiny Silver Slider Plating:

1. Make sure the sliders are separated well from the frame, when they were taken out from Die casting machine.

2. Make the required polishing process. For polishing the sliders, we can use different high-quality polishing machines. Those machines use polishing stones to make the polishing process complete.

Polishing Machine

The Main Process

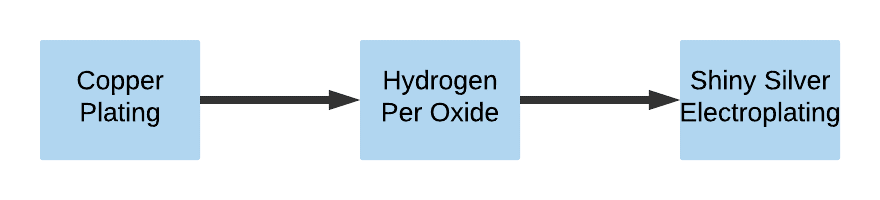

At first, the sliders go through the Copper Plating Machine (CPM), It requires 1.5 hours for copper plating process. All type of slider plating need to go through this plating process(Copper Plating) first. Otherwise we can’t have the expected color. Here is a sample copper plating machine.

Figure 2

(Copper Slider Plating Machine)

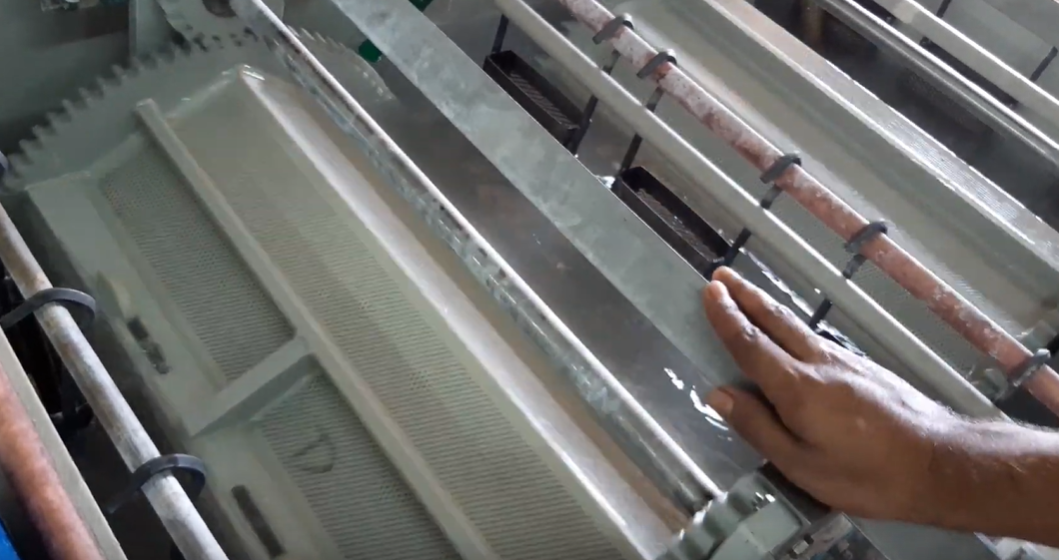

For Copper plating, we have some copper plates which works like Anode. For reference, In the Figure 3 we can see the marked materials which called copper plate and works like Anode.

In the other hand the whitish liquid is made by Sodium Solution. The slider product in the chamber works like Cathode.

Here the Copper Plates works like the source of electrons (Negative). From where the electrons flow through the whitish liquid to the zipper sliders (Positive) and make the copper plating. That plating process should be done at least 40 minutes to 1.5 hours according to slider color.

(We can use this Chamber according to slider quantity this machine has 2 Chambers)

Figure 3

Secondly, The Copper Plated sliders goes through hydrogen peroxide solution. Which increases the shining and glittering of the Copper Plated sliders in a good amount. It’s commonly available from pharmacies as a 3% solution in water, for slider plating we normally use 5% or 10% concentration of this material for slider shining.

Figure 4

(After Copper Plating and Shining with Hydrogen peroxide)

Thirdly, here is the final slider plating process of shiny silver. In this stage we have the copper plated zipper slider which is shined using hydrogen peroxide. Now we will make the zipper sliders go through our second slider plating machine. Which has several compartments for slider plating process for shiny silver color.

Step 1: The sliders goes through the first tank of the plating machine where we have different types of chemicals based on different colors we want. It uses 2 similar chemicals compare to the copper plating machine (Sodium and Copper Cyanide) but It also has 2 more chemicals one is Brass Salt another one is Brass BA which is called Ammonia Chloride.

Figure 5

Step 2: Here we make the sliders electroplated using shiny silver chemicals. We take the sliders into a chamber and make it electroplated for 40 minutes to 1 hour.

Plating Chamber:

Here we take the sliders from 10 minutes for Shiny silver and up to 40 minutes for different colors. It has total 2 main marts one is anode another one is cathode. The following port is Anode which is positive. The sliders inside the chamber works as Cathode.

Anode one is just took at left.

Things to consider to get best slider plating colors:

1. Rectifier connection and voltage

2. Chemical should be appropriate and best quality

3. Sufficient voltage at Cathode and Anode.

4. For Alloy Materials we need to make rolling for a long time and them mage finished products. Then we can give finished product to copper plating to get best shining.

Final product After all of the plating process:

Related Posts

-

Blog & NewsQLQ Wish All Mothers A Happy Ho

…

Mar 08, 2024

-

Blog & NewsNurse's Day

Whispering is your character, white clothes and white skirts are your characteristics, rescuing the dead and healing the wounded is your bounden duty, nursing patients is your sacred duty, you give patients selfless love, and you turn your…

May 12, 2022

-

Blog & NewsEid Mubarak

Although now we are going through a hard time because of covid -19, but we all believe everything will goes well soon. QLQ family wish you and your family all the best!…

May 05, 2022

-

Blog & NewsHow To Produce Invisible Closed

Our invisible zipper advantages: 1) The standard reciprocating fatigue of invisible zipper is ≥600 times, but our invisible zipper can reach ≥900-1200 times. 2) The standard tension of invisible zipper is ≥480N, but our …

Apr 22, 2022