——Nov 15, 2019Shiny Gold Slider Plating using Electroplating Method

Shiny Gold Slider Plating using Electroplating Method

Gold is a soft, yellow and glittery matter. Which preserves its color for a very long time. Its yellow light sparkles attract a buyer to keep that thing in his collection. Of the pieces of jewelry made by that special material all over the world. Even some raw materials plated with a small amount of gold using the electroplating methods and they look very attractive like real gold. In this article, we will discuss How we can make slider plating using electroplating way, So that it would look like a gold-plated zipper.

Figure 1: Gold bar.

Electroplating, is a way in which we make coating of one material over another. It makes a very strong coating that stays for a long time. After the coating the main material loses its own properties and looks like the materials from where we made the plating .

Note:

- Make sure the sliders are separated well from the frame, when they were taken out from Die casting machine.

- Make the required polishing process. For polishing the sliders, we can use different high-quality polishing machines. Those machines use polishing stones to make the polishing process complete.

Figure 2: Slider Polishing Machine

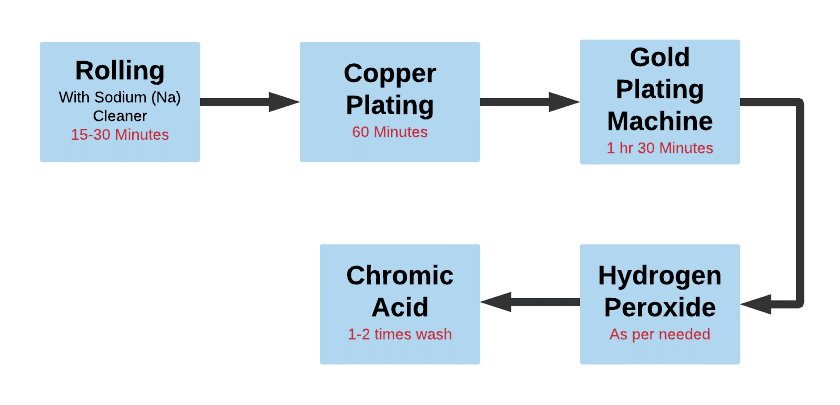

The main process

Figure 3

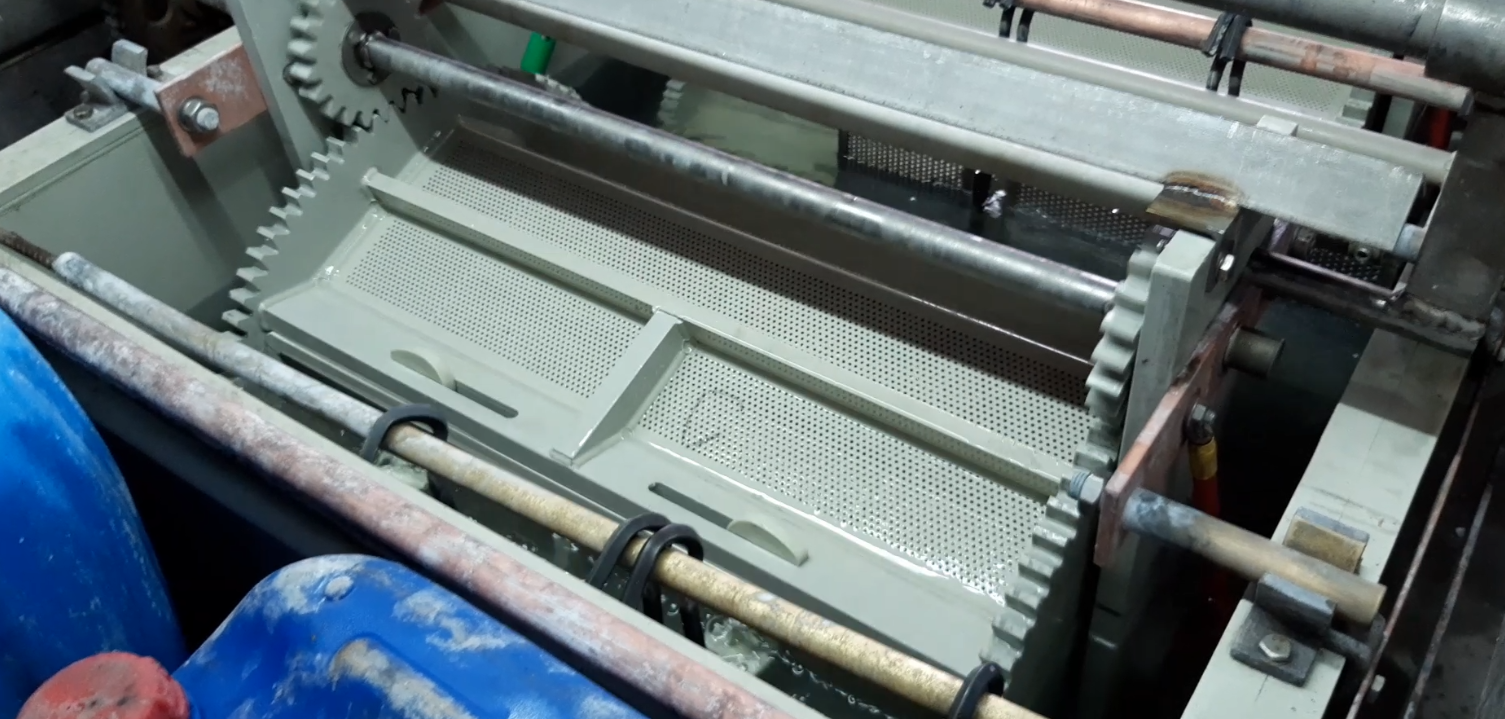

For Rolling, we take the raw zinc sliders into a rolling chamber that rotates clockwise. We add Sodium Cleaner Chemical inside the roller with the sliders. We need to do this process for 15-30 Minutes. It takes out all the dirt from the slider and makes it fresh. Also, if there any kind of layer over the slider body and puller, This Rolling process also removes it. Which makes the next plating processes effective and efficient.

Figure 4: Slider Rolling Machine

For Copper Plating, the sliders go through the Copper Plating Machine (CPM), It requires 1 hour for copper plating process. All type of slider plating needs to go through this plating process (Copper Plating) first. Otherwise we can’t have the expected color. Here is a sample copper plating machine.

Figure 5

(Copper Slider Plating Machine)

For Copper plating, we have some copper plates which works like Anode. For reference, In the Figure 6 we can see the marked materials at the left which called copper plates and works like Anode.

In the other hand the whitish liquid is made by Sodium Solution. The sliders in the chamber works like Cathode.

Here the Copper Plates works like the source of electrons (Negative). From where the electrons flow through the whitish liquid to the zipper sliders (Positive) and make the copper plating. That plating process should be done at least 40 minutes to 1.5 hours according to slider color.

(We can use this Chamber according to slider quantity this machine has 2 Chambers)

Figure 6

After Copper Plating the sliders looks like this. It fully becomes copper color. We will have to wash the sliders 3 times After the copper plating.

After washing we will take the sliders into the Gold plating Machine and make the plating for 1 hour 30 minutes. The Gold Plating Machine tank uses a chemical which made using the following concentration of different chemicals:

Gold Plating Tank

Then we will have to wash the Shiny Gold-Plated Slider once again with water. After washing we can see the color has been changed to gold color already.

To make it shinier we will have to wash it with Hydrogen Peroxide several times. Then the last challenge is to make the color long lasting so that it does not fade away for a long time. It will be done by Chromic Acid.

We will put the Hydrogen Peroxide shined sliders into chromic acid so that the color will be longer lasting. Then we will have to wash it again 3 times and Take it to dryer. It will make the sliders dry and produce the final product.

Shiny Gold Zipper Slider

Things to consider to get best slider plating colors:

1. Rectifier connection and voltage

2. Chemical should be appropriate and best quality

3. Sufficient voltage at Cathode and Anode.

4. For Alloy Materials we need to make rolling for a long time and them mage finished products. Then we can give finished product to copper plating to get best shining.

'

Related Posts

-

Blog & NewsQLQ Wish All Mothers A Happy Ho

…

Mar 08, 2024

-

Blog & NewsNurse's Day

Whispering is your character, white clothes and white skirts are your characteristics, rescuing the dead and healing the wounded is your bounden duty, nursing patients is your sacred duty, you give patients selfless love, and you turn your…

May 12, 2022

-

Blog & NewsEid Mubarak

Although now we are going through a hard time because of covid -19, but we all believe everything will goes well soon. QLQ family wish you and your family all the best!…

May 05, 2022

-

Blog & NewsHow To Produce Invisible Closed

Our invisible zipper advantages: 1) The standard reciprocating fatigue of invisible zipper is ≥600 times, but our invisible zipper can reach ≥900-1200 times. 2) The standard tension of invisible zipper is ≥480N, but our …

Apr 22, 2022