——Jul 24, 2019Setting Up a Bag Slider Factory

Setting up Slider Factory for Various Bags

Sliders are a component which combines two zipper tapes and creates a finished zipper. We open or close the zipper using slider by moving it up and down. There is a various quality of zipper sliders. In this article, we will be discussing dedicated bag sliders which can be used in your Luggage or Bag production house.

Things to be considered before production

Sliders are the most important part of any zippers. Because a zipper quality is depending on the slider quality. If we use a bad quality slider it will create quality less zipper which will create issues for the customers. So, If the case is for producing Luggage or Bag Sliders the quality can’t be compromised. Because it will be used frequently to open or close. It should also be lasting. SO, if you are making a slider for different kind of Bag or Luggage related products you will have to consider the following things:

1. Material used in slider

2. Slider color

3. Slider Size

4. Slider Durability.

-

Slider Material:

As we all know that luggage or bag sliders are manufactured for contentious heavy usage. So, the slider body materials should have to be very pure and strong. Which would not be broken at day to day usage. In that case, you are suggested to buy high quality Zinc materials which can make the slider stronger and long lasting. Zinc is a bluish metal which shows good strength in critical usage and contentious stress testing. So If you use good material like zinc you would have less worries about the strength of your slider body.

-

Slider Color:

If you are producing slider for your Luggage company then it should have to be attractive. Because there are a lot of competitors in the market. So, Customers usually buy the one that is eyecatcher and beautiful. Which will give them a premium look. And to give any type of bag a premium looks a zipper slider creates a very good role. Because if you use a well designed and polished slider. It will definitely attract the customers more. You can use Shiny Silver, Gold or Nickel colors for making shiny effect into the zipper. You can give those sliders a good shape from the mould machine. If you want to make anti colored sliders it is also possible. Like Anti-brass, Anti- silver Etc. Slider plating is the best way to add a genuine and attractive effect upon sliders.

Figure 1: Non-lock Slider

-

Slider Size:

We normally use 3-5 size sliders for garment productions but in bag production procedure we will definitely use a bigger and stringer one. So, the size will be 8-10 according to the zipper tape size. Also you might need smaller sliders for smaller bags. But you will just have to change the mould size for produce those. Also you will have to be sure the slider fits the zipper tape well.

-

Slider Durability:

Slider durability depends on the materials we are using in it. But After using the best materials we will have to make some tests to find if our created zipper is well durable or not. There is different stress testing for zippers. Like Pull Test, Key Test or Fatigue Test etc. If the produced zipper passes all of those tests then you can call it well durable zipper.

Setting Up Luggage or Bag Slider Factory

Once you know the requirements now you are ready for the production. This process is mainly divided into 3 steps,

1. Choosing slider body measurement.

2. Selecting Slider Puller Design.

3. Setting the color strength and design of the zipper puller.

-

Choosing slider body measurement:

There are different sizes of sliders Like #3, #5, #8, #10 etc. For your Bag you will have to determine which size of slider body you want to produce. From slider body size, our company will define the mould size. The molds and the zinc metal will be given into die casting machine to create initial zipper slider body and pullers. The wastage of zinc can be re used later. Normally Luggage and bag zipper slider body size is #5, #8 and #10. To produce those Slider bodies, you can select different good quality die casting machine depending on your requirement. There are 15 Ton, 20 Ton, 25 Ton and 30 Ton based die casting machines based on the quantity of slider body, the speed in one casting. Various die casting machines available in market. QLQ Enterprise also provides you quality Die Casting Machines.

Figure 2: Die Casting Machine

Figure 3: Die Casting Mold(Slider Body).

After die casting the slider bodies are combined into mould and looks like this.

-

Selecting Slider Puller Design:

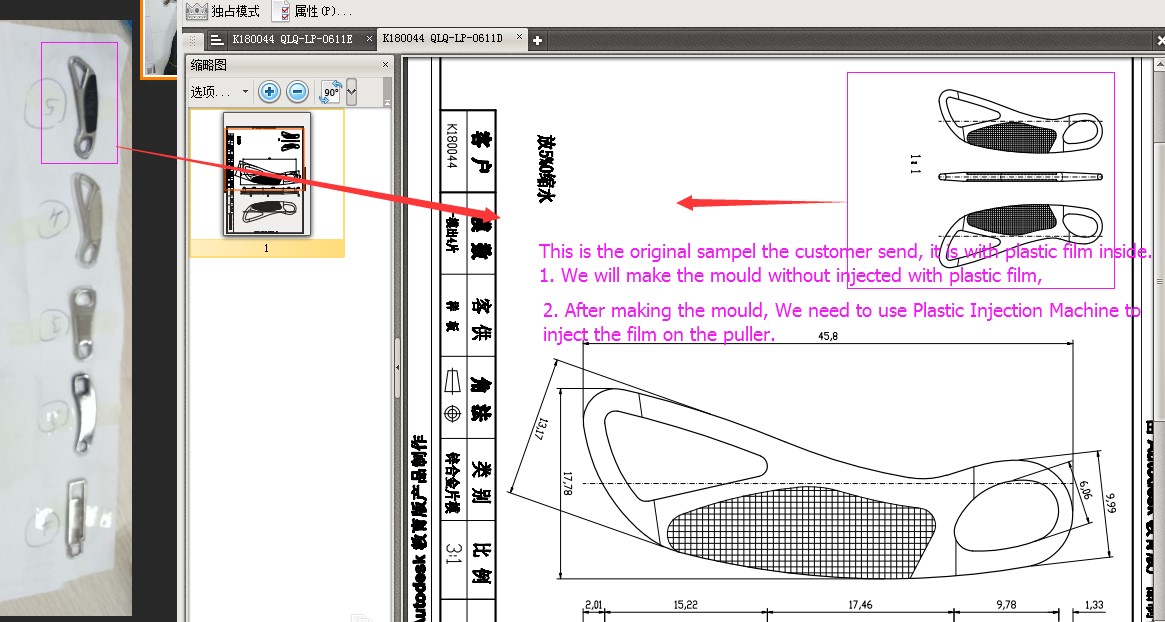

Once you select the slider body size then you can select any kind of puller design you want. You can copy a puller design that is in the market already or create a new puller design based on your requirement. The design will be stamped into the puller mould using a computer. The slider mould manufacturers do that process using automated computer.

The screenshoot shows you how we make a replica design into our computer to produce any sample slider puller. We can make 99% similar design from a sample slider that is given from a customer to us. You can use same Die Casting Machine that has been used in the slider body production. What you need to change is the mould only. You can create different puller body mould for different puller design.

- For more information you can also check the YouTube video. After the die casting process when we take the puller mould out it looks similar like this.

-

If the customer wants to take the puller mould we can give them like this. They can add color to it by painting or plating later on.

-

Slider Assembly:

After producing Slider body and puller, we will have to Assemble the parts of the slider. For this you can go for manual way, that is by hand, where you can take some labor to assemble the slider parts. But it takes time and a lot of efforts. We also offer automated slider assembly machines. Using this machine, you can assemble the sliders very easily. What you will have to do is just put your manufactured parts into the machine and that’s all.

-

Painting & 2. Plating. Painting process is simple but it looks less attractive and after using the zipper for some days they paint starts fading away. But in the other hand the plating process makes the color more attractive and longer lasting.

You can do slider plating in manual way by hand or using slider plating machine.

You can contact with us if you need more information.

Related Posts

-

Blog & NewsQLQ Wish All Mothers A Happy Ho

…

Mar 08, 2024

-

Blog & NewsNurse's Day

Whispering is your character, white clothes and white skirts are your characteristics, rescuing the dead and healing the wounded is your bounden duty, nursing patients is your sacred duty, you give patients selfless love, and you turn your…

May 12, 2022

-

Blog & NewsEid Mubarak

Although now we are going through a hard time because of covid -19, but we all believe everything will goes well soon. QLQ family wish you and your family all the best!…

May 05, 2022

-

Blog & NewsHow To Produce Invisible Closed

Our invisible zipper advantages: 1) The standard reciprocating fatigue of invisible zipper is ≥600 times, but our invisible zipper can reach ≥900-1200 times. 2) The standard tension of invisible zipper is ≥480N, but our …

Apr 22, 2022