-

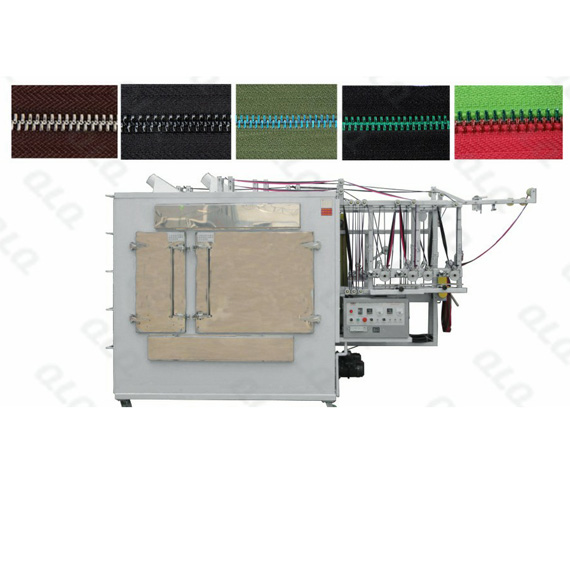

QLQ-MLM2-2 Automatic Metal Zipper Surface Multifunctional Crystal Lacquer Machine (two line, two chambers)

Summary : This machine is used to iron, finalize and coat lacquer for metal zippers of which with gold, silver, anti brass color, or mirror face and bright face effect.

Product Name: Automatic Metal Zipper Surface Multifunctional Crystal Lacquer Machine (two line, two chambers)

Model number : QLQ-MLM2-2

Summary : This machine is used to iron, finalize and coat lacquer for metal zippers of which with gold, silver, anti brass color, or mirror face and bright face effect.

PRODUCT DESCRIPTION

This machine is used to iron, finalize and coat lacquer for metal zippers of which with gold, silver, anti brass color, or mirror face and bright face effect. After processed by this machine, zipper has a bright, shiny and third dimension feeling lacquer Coating which helps to improve the appearance and increase the value of zipper as well as effective ensuring zipper will not easily discolor or oxidized in future application.

This machine is soldered by 3mm cold metal plate, and most of electric components are imported. The machine adopts high-temperature bearing, imported heat, special tape running system, window-shades air supplier system, tension control system, highly effective cooling System And Scientific lacquer applying system.

| Machine Model | Average Output | Total Power | Voltage |

Machine Size (cm) L×W×H |

| QLQ-MLM2-2 | 1250-2500M/H | 21KW | 380V | 440*120*220 |

Advantages:

1- This machine adopts two ovens which are completely separated and up & down tape running way.

A) Moisture and smoke of plated zipper are completely dried in the first oven. The steam with oil fume is discharged rapidly.

B) The second oven helps to make lacquer and zipper completely contact after lacquer coating. Zipper is sealed in a good environment without oil fumes or steam, which makes sure zipper will not discolor, lacquer even, with strong third dimension feeling and durable for water Washing.

2- Individual tension system and cooling system makes better zipper radian and lower shrinkage rate so that zipper will not deform easily in the future application.

3- A remote control is equipped for easy human operation, equipment maintenance and tape crossing.

After waxing, zippers will be sent back to the oven again so that the wax will be completely melt onto the zipper to achieve smooth pulling feeling without leaving any wax mark on the tape.

5- This machine can also coat lacquer on corners of teeth head to seal zipper surface completely so that zipper will not discolor easily.

6- Zippers processed by this machine are durable for acid washing, strong ferment washing and water washing.

7- Colors can be added to lacquer to greatly improve zipper value.

8-The length of zipper running inside the oven is about 300m which effectively ensure the baking time so that the ironed zippers are not easy to deform, more soft and hardness of surface lacquer reaches 5-6H.

9-A scientific lacquer applying system makes zipper lacquer coating eve, glossy, smooth and with extremely strong third dimension feeling.

10-Air supply system adopts window-shades, making hot wind run all over the oven, which practical ensure even temperature of each location of the oven.

11-All excellent materials from famous branded suppliers at home and abroad makes quality guarantee coefficient increased 5 times.

Chat Now!

Chat Now!