——Feb 09, 2019Metal Zipper Plating Process

There are three techniques of plating metal sliders: 1. Redox 2. electroless nickel plating. 3. Painting

1. Redox:

Redox (short for reduction–oxidation reaction) is a chemical reaction in which the oxidation states of atoms are changed. Any such reaction involves both a reduction process and a complementary oxidation process, two key concepts involved with electron transfer processes. Redox reactions include all chemical reactions in which atoms have their oxidation state changed; in general, redox reactions involve the transfer of electrons between chemical species. The chemical species from which the electron is stripped is said to have been oxidized, while the chemical species to which the electron is added is said to have been reduced. It can be explained in simple terms:

Oxidation is the loss of electrons or an increase in oxidation state by a molecule, atom, or ion.

Reduction is the gain of electrons or a decrease in oxidation state by a molecule, atom, or ion.

Our Zipper Plating Machines uses Redox process for any kind of

Zipper Plating. It is more Stable and very long lasting than any

typical Electroplating process.

2. Electroless Nickel Plating

Electroless nickel plating is an auto-catalytic chemical method which is making possible to put a layer of nickel-phosphorous or nickel-boron alloy, on a solid object made of metal or plastic. Unlike the other plating technique, electroplating, this one can be used on complex shapes and non-conductive objects, because is not using electrical current.

3. Painting:

Painting can be done for different Zipper Slider using machine or painting gun. Machine is automated and Painting Gun is manual. We can load different colors into these and start painting the zippers. They should be sent to oven to make those colors dry. There are automated zipper painting machines.

How to Make Metal Zipper Plating

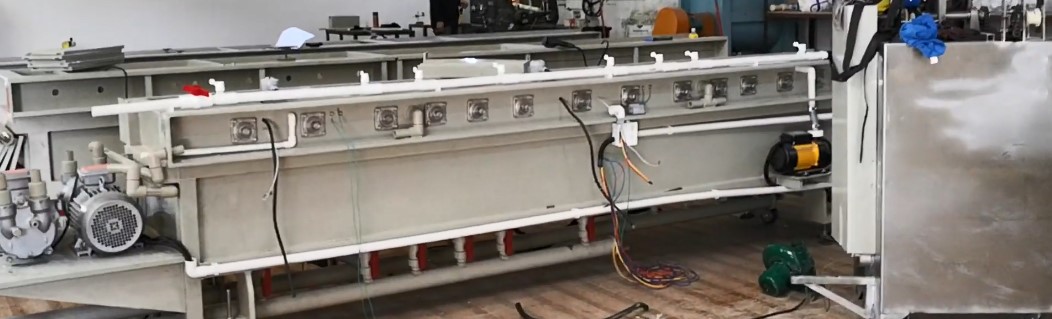

Our QLQ Metal Zipper Plating Machine is a single templating machine. Every time we make this product for customers, we test it at least three days with affective empathy learning. Where we try to think what would be our customer's experience or opinions during operating the machine. Which helps us to make that product very smooth, user-friendly and safe for the customers when they receive the machine.

The Process

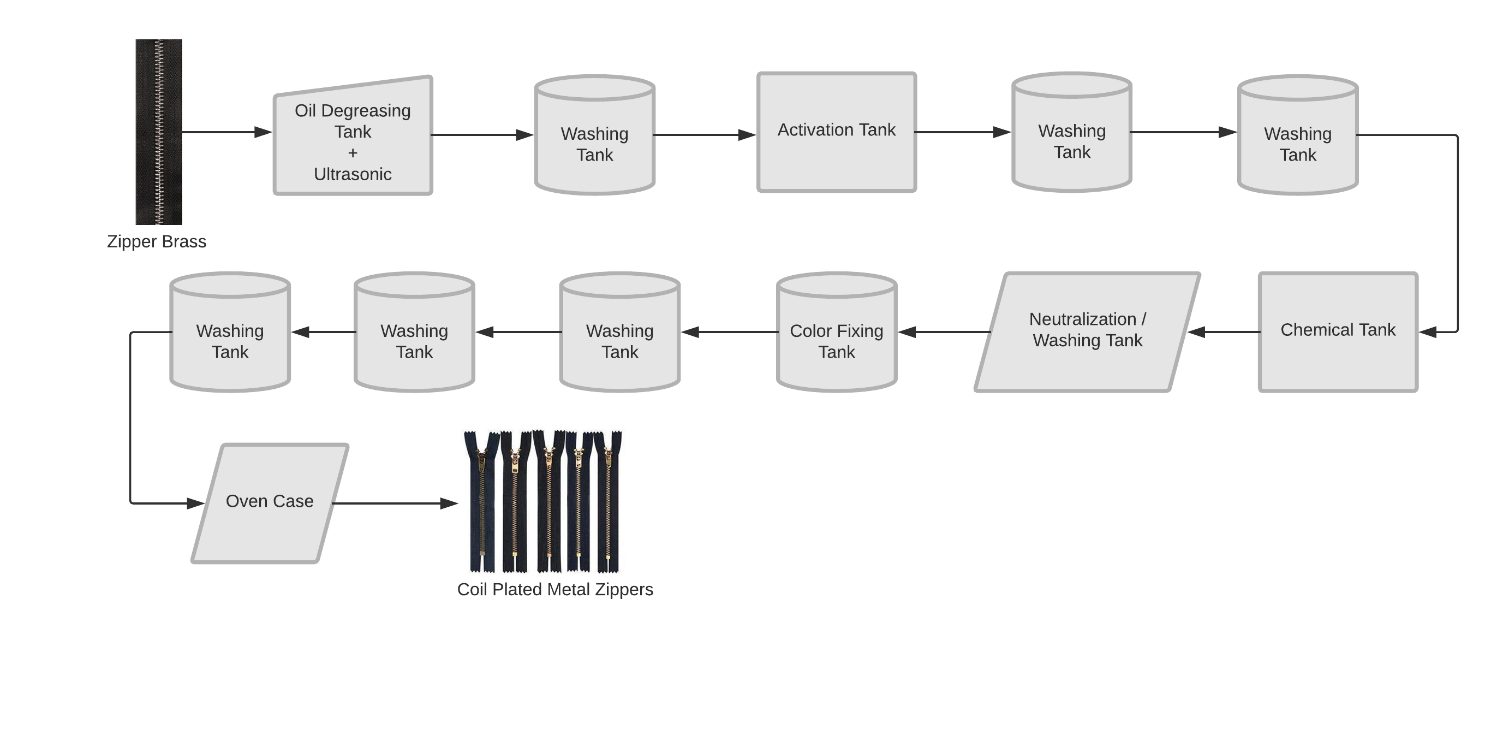

The following diagram shows a summary of how the Metal Zipper (Brass Material) goes through different processes.

Machines Needed:

|

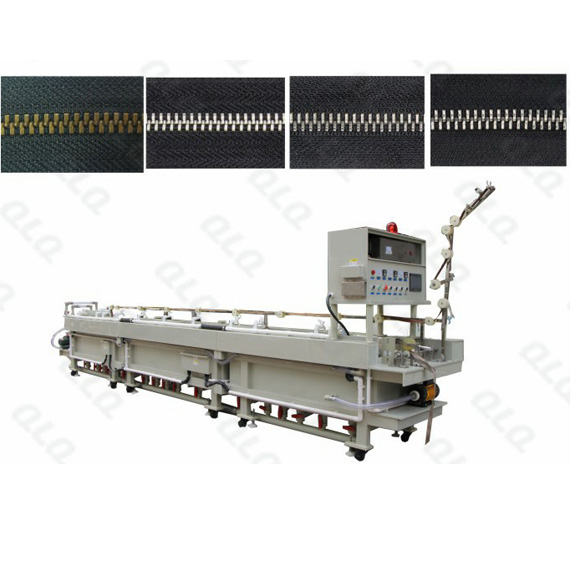

Automatic Metal Zipper Shiny Gold Plating Machine

QLQ-HGPM

This machine just make shiny gold color.

|

Automatic Metal Zipper Chemical Cold Plating Machine(with one chemical tanks) QLQ-CCPMS This machine can make nickel,anti-brass, gun color. If zipper is after shiny gold plating first, then this machine can make shiny nickel, shiny light gold, shiny gun also. Please contact us anytime if you want to know more detailed information. sales@qlqcompany.com, cathy@qlqcompany.com Mrs.Cathy wechat/whatsapp/tel No.: 008613316184685 |

|

Automatic Metal Zipper Chemical Cold Plating Machine

QLQ-CCPMD

This machine can make gun color/anti-brass color, nickel

color, anti-silver color. If zipper is after shiny gold

plating first, then this machine can make shiny gun, shiny

nickel, shiny anti-silver also.

|

Automatic Metal Zipper Cleaning & Color Fixing

Machine (after plating) (economic model ) QLQ-CMAP

This machine is for zipper plated color fixing and clean

chemical which stick on the zipper tape well

|

|

QLQ-MLM Metal Zipper Automatic Multifunctional Crystal Lacquer Machine (one line, one chamber)

Summary : This machine is used to iron, finalize and coat lacquer for metal zippers of which with gold, silver, anti brass color, or mirror face and bright face effect. |

|

First, the Zipper goes to “Oil Degreasing Tank” which removes oil from the teeth of the zippers, If the metal zipper is after shine coil plating then no need to remove oil from it. it has a feature called “Ultrasonic”. For “Ultrasonic” you

can decide to buy that feature or not. The second tank is a washing tank where the metal zippers sent after degreasing. From there the zippers pass through one “Activator Tank” and two “Washing Tank”.

Chemical Tank where the chemicals are supplied. We can manually control the

supply of the chemical from the control board. Using high pressure

chemicals spraying system to prevent zipper concave point scratched and

improve chemicals reaction effect to make more stable and bright color.

Zippers are completely soaked in chemicals in the chemical tank, which

improves reaction time and effect, saves chemicals cost and improves zipper

quality.

Chemical Tank where the chemicals are supplied. We can manually control the

supply of the chemical from the control board. Using high pressure

chemicals spraying system to prevent zipper concave point scratched and

improve chemicals reaction effect to make more stable and bright color.

Zippers are completely soaked in chemicals in the chemical tank, which

improves reaction time and effect, saves chemicals cost and improves zipper

quality.

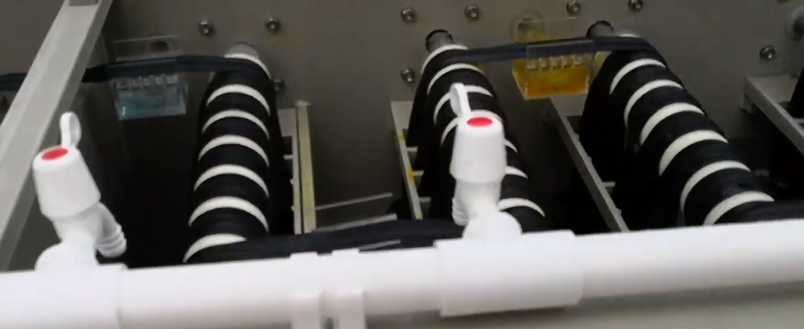

Flap wheels system makes chemicals have more complete and faster reaction.

The plated color is more stable & brighter, wash

more clean and lower cost.

From the Chemical Tank, the metal zippers are sent to “Neutralization Tank” and “Washing Tank”. If we make the nickel coil plating, we will have to do the neutralization otherwise if we do the gun color or anti-brass, we do not have to send it through “Neutralization Tank” we can just send it through washing tank.

Then the metal zippers are sent to “Color Fixing Tank” which makes the color shinier and more beautiful. From there it flows through three “Washing Tanks” which removes the chemicals from the zipper very well.

some cleaning or washing processes. When it comes out, the zipper sent to an “Oven Case” so that the plated nickel color can be more long-lasting. Now the zippers are ready to be shipped.

We make varieties of Metal Zipper Plating Machines for our customers. So, if you are int

erested feel free to contact us

Related Posts

-

Blog & NewsSimple Answer for some of the Z

Simple Answer for some of the Zipper Related Questions…

Feb 28, 2019

-

Blog & NewsTypes of Zippers

Zippers come in a variety of lengths, types and materials, so always select the best zipper type and material to improve the appearance and durability of your sewing project. Zipper teeth are manufactured from three types of materials—met…

Feb 09, 2019

-

Blog & NewsMetal Zipper Plating Process

There are three techniques of plating metal sliders: 1. Redox 2.electroless nickel plating. 3. Painting 1. Redox: Redox (short for reduction–oxidation reaction) is a chemical reaction inwhich the oxidation states of atoms are changed. Any…

Feb 09, 2019

-

Blog & Newsplastic zipper production

Long Chain Plastic Zippers Plastic Zippers are identical to metallic zippers, except that the teethare plastic instead of metal. Metal zippers can be painted to match thesurrounding fabric; plastic zippers can be made in any color of plasti…

Jan 30, 2019